Advantages

- Safe operation (no fractures) because of seal face locking by square pin

- Spring unit averted from the product so no sticking and clogging of the springs

- Suitable for pressure reversals

- Operation in vacuum without additional seat locking possible

- No damage of the shaft by a dynamically loaded O-Ring

- Small installation sizes

- Best suitable for conversions, no adaptations of the pump

- Insensitive to solid containing and abrasive media

- Advantages of a balanced seal even with plain shafts

- Insensitive to shaft movements because of the stationary design

Features

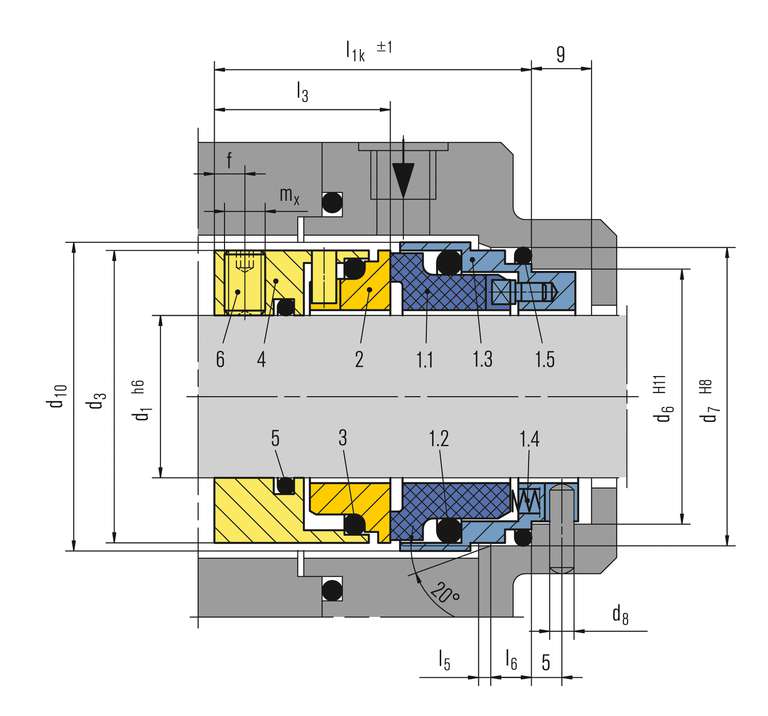

- Single seal

- Balanced

- Independent of direction of rotation

- Stationary springs

- Dual seals in tandem as well as back-to-back arrangements (also in combination with H10 seal)

Materials

- Seal face: Carbon graphite resin impregnated (B), Silicon carbide (Q1)

- Seat: Silicon carbide (Q1)

- Secondary seals: FKM (V), NBR (P), FFKM (K), PTFE (T)

- Springs: Hastelloy® C-4 (M)

- Metal parts: CrNiMo steel (G)

Recommended applications

- Water and waste water technology

- Refining technology

- Dirty, abrasive and solid containing media

- Fugitive hydrocarbons (no API seal!)

- Sticky and stringy media

- Chemical standard pumps

- Sewage pumps